Xpact Production

Efficient AI-based process automation and document processing in wholesale and manufacturing industries

Hundreds of orders arrive in your mailbox every day. Processing them takes time, ties up employees, and is often prone to errors. Our software solution takes care of the fully automated processing of your documents thanks to our own AI.

Intelligent automation – Up to 99% savings!

Xpact Production Specializes in document processing in the manufacturing and wholesale sectors. Fully automated and data protection-compliant processing and analysis of documents in production, including orders, order confirmations, tenders, etc.

Self-developed

AI “Made in Germany”

Zero-touch processing trough SOC certification

No data mixing:

AI only trains with your data

Small number of documents

required for training

Pre-trained software for a productive start

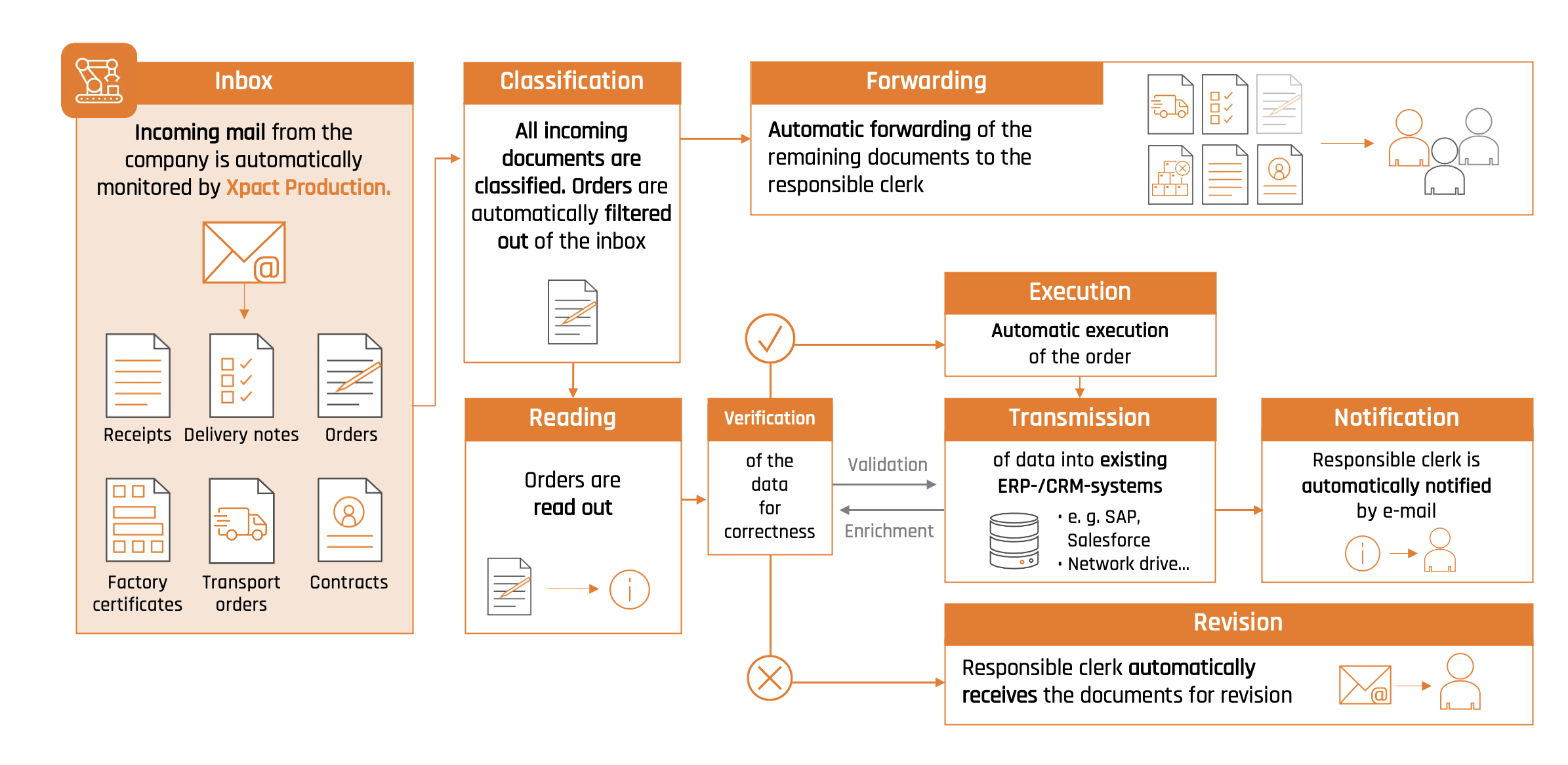

This is how automated document processing works with Xpact Production:

Xpact Production accompanies the document every step of the way: Starting with the classification of the document, the type of document is determined.

All relevant information is then read out and stored in your existing IT system.

Upon request, the collected data can be validated and enriched by comparing it with your database.

Learn more about Xpact Production and download our product information now:

Weitere Bereiche für Ihre Prozessautomatisierung

Previously, processing a single order manually took around four minutes. With the help of AI-based software from Evy Solutions, Antalis reduced processing time to an average of 15 seconds – a time saving of over 90 percent.

Rouven Bartmann, IT-Systemadministrator antalis

Xpact Production in der Praxis

Read here about the success stories we have already achieved with Xpact Production:

Get started now and arrange a free

demo!